designed to control heat transfer on surface temperatures up to 250°C

HPC COATING

It is waterborne and extremely lightweight in appearance. HOT PIPE COATING offers a “Green”, non-flammable, non-toxic formula for high temperature surface applications. Engineered to be applied over hot pipes or other high temperature surfaces to achieve instant adhesion while immediately lowering the temperature of the hot surface.

Project Description

There was a need to conserve energy and prevent corrosion under insulation of an Ingersoll Rand gas compressor on one of the off-shore platforms. Furthermore, an important aspect of the project was to reduce operating temperatures (170°C to 60°C & 220°C to 60°C) in order to prevent the staff from being exposed to unacceptable temperatures. The application needed to be done while the equipment remained fully in operation.

Coating Solution

With the use of Graco equipment the HOT PIPE COATING was applied by spray with a thickness of approximately 24mm-20mm wet to be between 18mm-15mm dry.

RUST GRIP was then applied with a thickness of 8 mils wet to get to 4 mils dry.

Finally ENAMO GRIP was applied with a thickness of approximately of 10 mils wet to get 5 mils dry.

Project Description

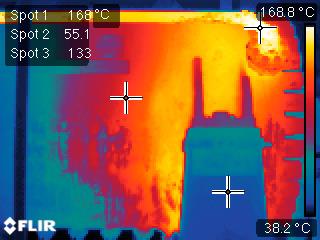

There were oil pipelines and heat exchangers that need to be insulated, the operating temperature was equal to 220°C, the required surface temperature was 55°C. The customer was looking for a maintenance free solution, due to the fact that the site was also located at a remote area where structural maintenance was expensive and not a real option.

Coating Solution

The site where the project was completed was 100 meters pipeline (including heat exchangers and valves) measuring a total area of +/- 110 m². To achieve the rated level of heat losses and temperature reduction at the surface to 55°C, with the use of Graco equipment the HOT PIPE COATING was applied by spray with a thickness of 15mm.

Project Description

Purpose of the project was to ensure temperature control for used Oil Recycling Tank, Heat Exchanger, and Pipelines in order to ensure workers safety and physical protection.

Coating Solution

Application area : Boiler Condenser (Heat Exchanger), Tanks and Pipelines (Total: 1,100m²) Stainless Steel (Tank), Carbon Steel (Boiler outer surface, Pipes)

Application method :

Pressure-wash: Removed all oil residues from the surface

HPC was applied in 3 layers (Total 5mm wet thickness)

Come & try our PRODUCTS

we always give the best price