THERMAL INSULATION PT. PRYSMIAN CABLE INDONESIA

THERMAL INSULATION

Problem Case Description:

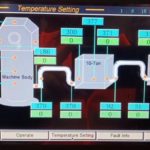

PT. Prysmian Cable Indonesia has a problem of safety working in their Lead Extruder area due to its thermal exposure to the environment. It is a machine that has purpose for melting lead in order to be used as one of cable component. In the process of melting and extruding the lead, it needs constant heat from element/ heater at around 375oC. Even tough this machine has already completed with rockwool insulation with 25 cm thickness, high temperature still appears at surface at around 90oC – 147oC.

This high temperature creates unsafe working area due to the risk of getting touch by worker as well as affecting in uncomfortable condition to work.

Proposed Solution:

Considering the core issue and the needs of PT. Prysmian Cable Indonesia to create safe working area at Lead Extruder, PT. Mahita Karya Persada Teknik (MKPT) Coating and Insulation Division proposed to use Hot Pipe Coating (HPC). It is ceramic based coating that has purpose to block heat transfer from inside machine to the environment.

Hot Pipe Coating (HPC) is applied by spray method so it can conform to any kinds of profile and surface of Lead Extruder machine. It is water-based coating with special resin so it can be applied directly to metal surface of Lead Extruder after being cleaned.

As the concern issue is safety working area, Hot Pipe Coating (HPC) is applied at minimum 12.5 mm DFT. We expect to create finish temperature at 60oC which already comply to ASTM ‘five second’ safe to touch rules.

Rust Grip is then applied as finished coating for protection from outer contaminant it may have risk of being contaminated by liquid lead when the machine operating.

Result:

After Hot Pipe Coating (HPC) application, finish temperature appears at around 60oC with 13-18 mm DFT, and already create safe working area nearby the machine.