CORROSION CONTROL PROJECT BEAM STRUCTURE SEA WATER INTAKE AREA PT. SMELTING INDONESIA

THERMAL INSULATION

Problem Case Description:

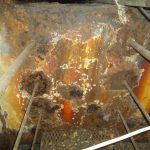

PT. Smelting Indonesia had a corrosion problem in inside sea water intake area, especially on its beams structures due to old painting and corrosion control system. Three coat painting system was used as surface protection material to keep the metal structures from getting corroded. Unfortunately, the protection system cannot withstand to intensive sea water splash in the area. Because of the old painting and continuous contact to sea water splash/ vapor, the corrosion cannot be prevented.

The problem was observed when there were annual shut down at plant. An immediate action has to be taken to to stop corrosion at beams structure inside sea water intake area within limited time at around six days. Normal corrosion control system by using sandblasting and three coat system would not be possible to deliver.

Proposed Solution:

PT. Mahita Karya Persada Teknik (MKPT) Composite Division proposed to do corrosion control on wharf structure using Rust Grip at around 250 microns DFT plus Rust Grip-E as top coat at around 150 microns DFT. Rust Grip is specialized to stop corrosion from inside through penetrating and encapsulating technology, while Rust Grip-E would be outer guard material that familiar to wet area and protecting the metal from sea water splash and vapor.

The process is started by cleaning all existing surface by mechanical and hand tools cleaning, especially for some severely corroded area. No sand blasting is required, so it safe more time. After all surface cleaned from loose pieces, then ChlorRid is applied by spray to clean up salt contaminant on the matal. After ChlorRid reaction inside metal pores, rinsing with water by using pressure wash. The first Rust Grip application is applied using brush to help the material penetrate into the pores of metal. As finishing, build up Rus Grip-E taken by using roller nap.

Result:

Job can be delivered on time at only around six days period. After application, beams structure inside sea water intake is rehabilitated and completely protected from corrosion and sea water splash. PT Smelting can start their operation inside sea water intake safely and securely.